April 5, 2020 by Carol Britton Meyer

Hingham Middle Schooler Lauren Armstrong, 11, is sewing face masks for nursing homes on the South Shore -- a true labor of love.

"It breaks my heart to think of elderly people getting this virus," she said. "I figured one way I can help is to make masks to help protect them."

She is among a number of Hingham residents who are involved in this worthwhile effort, whether part of the Face Mask Task Force, another group, the Derby Academy 3D project, or as an individual during the ongoing personal protection equipment shortage in the healthcare field.

These mask-making efforts draw on a range of techniques, from hand- and machine-sewing to 3D printing.

Lauren is also making face masks for neighbors. "They've already put in their orders," said her mother, Molly Meyers. "She's on a mission to make 200 masks."

Lauren, who took sewing classes last year, is using a pattern she found online. Fabric remnants gathered over the years from family members, including Lauren's grandmothers, are being put to good use now.

In celebration of the arrival of spring, she and her mother went to the Merimekko store in Boston before non-essential businesses were ordered to close due to the coronavirus threat and bought material featuring Easter designs in bright and cheerful colors. Lauren uses a sewing machine while her mother does all the hand sewing.

"We've been trying to find elastic for the face masks, but it's sold out everywhere, so we're using coated hair elastics, which are working just fine," Meyers said. "We've jumped through a couple of hoops along the way like when the bobbin got jammed and we had to watch a YouTube video to fix it. Lauren has made 40 face masks so far, with a lot more to go! This is such a great activity."

Overwhelming response

The Hingham Face Mask Task Force has its roots in a March 19 Hingham Pinboard post by Dr. Lori Lerner, a Hingham surgeon, sharing that she had instructions for cloth masks with filters and was looking for people who could sew and had time on their hands. There was an overwhelming response, which led to the creation of the task force.

When Jeanine Murphy, a Hingham resident and nurse, put out the word that local hospitals were in need of gloves and face masks, Jill Palese decided she could put her fashion design background to good use in a different way. "It was then that I realized the severity of the situation," she said. "I took out my sewing machine and reached out on Facebook for more volunteers and also connected with Lori."

As background, the medical professionals at surrounding hospitals are in immediate need of face masks due to a shortage of N95 masks -- meaning that the mask can filter out at least 95 percent of particles of all sizes from the air.

As a result they have been asked to wear bandanas to cover the masks that they’ve been issued to protect them until they are restocked with appropriate medical masks.

That's where the task force comes in, sewing cloth masks as covers to preserve the N95 -- with an inner filter and tight around the face, which adds another layer of protection.

"Lori guided us on the best way to make the covers," Palese said.

These face masks, the design of which task force members improved as a team, are larger than some styles. Palese noted that because they provide more coverage, they are a physical reminder not to touch your eyes, nose, and mouth.

On April 4 the CDC recommended bandanas and scarves in the absence of masks for the general public.

Lerner pointed out that cloth masks are useful for non-critical healthcare workers -- those who don't have face-to-face contact with patients -- for use in the office and for their families. This helps slow the demand for surgical masks that are needed by frontline medical professionals.

"What's been really nice is that task force members have developed virtual connections with people sharing a common cause. They have the time and energy to do something to help," Lerner said.

Palese's goal is to make dozens a day of what have come to be called "The Hingham" masks, with help from her daughter.

It's not uncommon to communicate with other task force members as many as 10 times a day. "I feel as though they are my best friends, and I haven't even met most of them in person because of social distancing guidelines," Palese said.

Other task force members besides Lerner and Palese include Michael Sabatini, Christine Nielsen, Lana Odell, Kenzie Blackwell, Becky McLeod, Brooke Bartletta, Rindy Hesselman, and Maria Bromley, each bringing their own unique skill sets to the effort.

Palese also expressed appreciation for Dan Power, who along with other Hingham residents, founded the HinghamLink website and offered support to the task force. HinghamLink is a volunteer service connecting people that want to help with people that need help.

Palese feels a connection with others who are making face masks. "We're all doing the same thing everywhere in the world," she said, "although it's not something we thought we would be doing."

Michael Sabatini is also a member of the task force, offering his graphic design skills to the mix. At first he made face masks he designed himself -- 280 in three days -- and more recently designed the task force logo and a tag that includes washing instructions, and now he handles its social media postings.

"We're all dedicated to the cause, and meticulous about the craft and what we are creating," he said.

So far, the task force has given out more than 200 face masks to the VA Boston Healthcare System, where Lerner works, Brigham & Women's and South Shore Hospital, and VA rehabilitation facilities.

"Everyone wants them and likes them," Lerner said.

There's a collection box at St. John's in downtown Hingham for face masks and other donations needed by the medical field.

For further information abut the task force, the face mask-making process, and how you can help, visit https://www.hinghamlink.com/posts/facemasktaskforce

Click here to view Lerner's video about how to construct "The Hingham" homemade surgical mask: https://m.youtube.com/watch?v=m6gcG4n1EF0.

'We're just trying to connect'

Hingham resident Melissa Smith is working with fellow resident Katie McBrine, a pediatrician, and other friends who have sewing machines to produce face masks.

"We provided 10 face for a family with at-risk members and some for friends and others who needed them," Smith said.

She and McBrine also distributed face masks within the medical community and to a counselor who continues to see patients every day. One of Smith's friends from Scituate is sewing face masks for MBTA workers.

There are a number of different face mask designs, and McBrine is providing guidance on how to make the face masks and to decide what kind the group would like to make, and for whom, and then to get the masks to those who need a particular design the most. These include masks for patients receiving care at a healthcare facility to help stop the spread of the disease.

"We're trying to connect with those who need face masks and to be sure we provide them with the right kind," Smith said. "Some are made with a pouch to hold a filter for healthcare workers, with a pleated design and metal nose piece. These take a little longer to make, but it's worth it because they provide extra security."

Because elastic is in short supply, Melissa found online a way to instead use long pieces of cut-up t-shirts to make a head wrap.

Smith's husband, Benjamin, is producing masks from a 3D printer that she said are comparable to N95 masks.

Derby Academy joins the effort

Derby Academy is also answering the call for help in making face masks in the face of the critical nationwide shortage.

Academy faculty member and STEM Curriculum Coordinator Kathleen Malone is answering the call and 3D printing the protective masks with the help of Derby’s fleet of 3D printers. Malone was inspired after speaking with a group of educators who were eager to assist those on the frontlines of the coronavirus pandemic.

“This meaningful application of our curriculum and resources resonates with our students and the entire community," Malone said. "It tells a nice story about how we’re giving back at a time when we’re all feeling the desire to help,” Malone shared from home. “Doing something, regardless of how small, always lifts the spirit.”

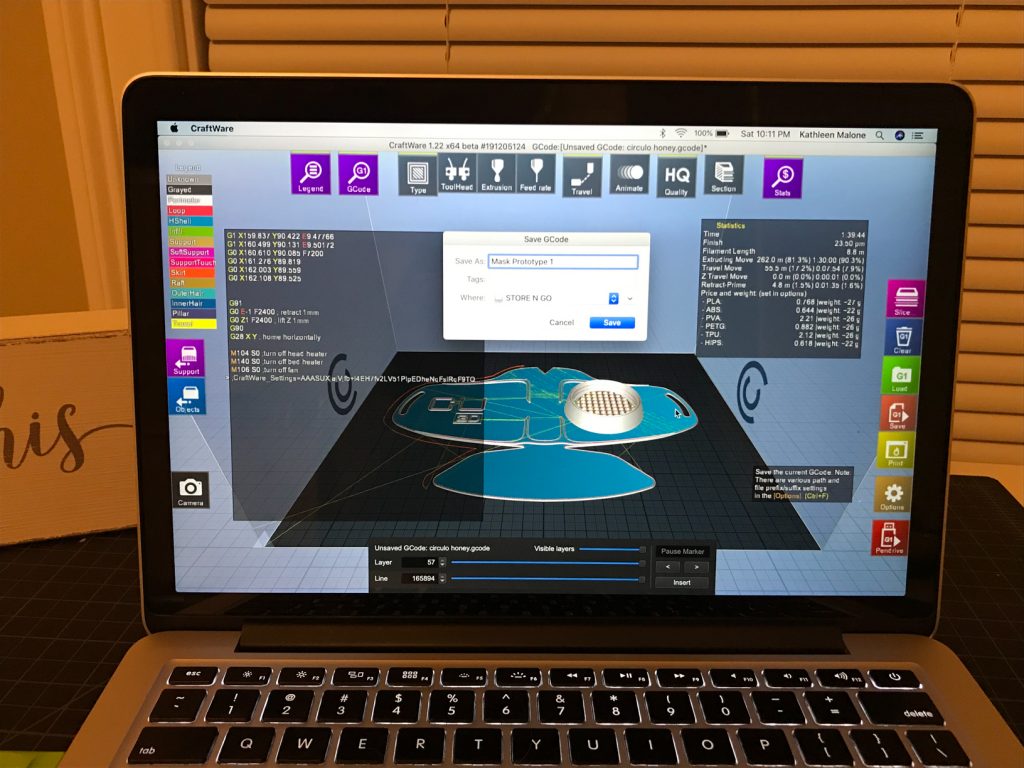

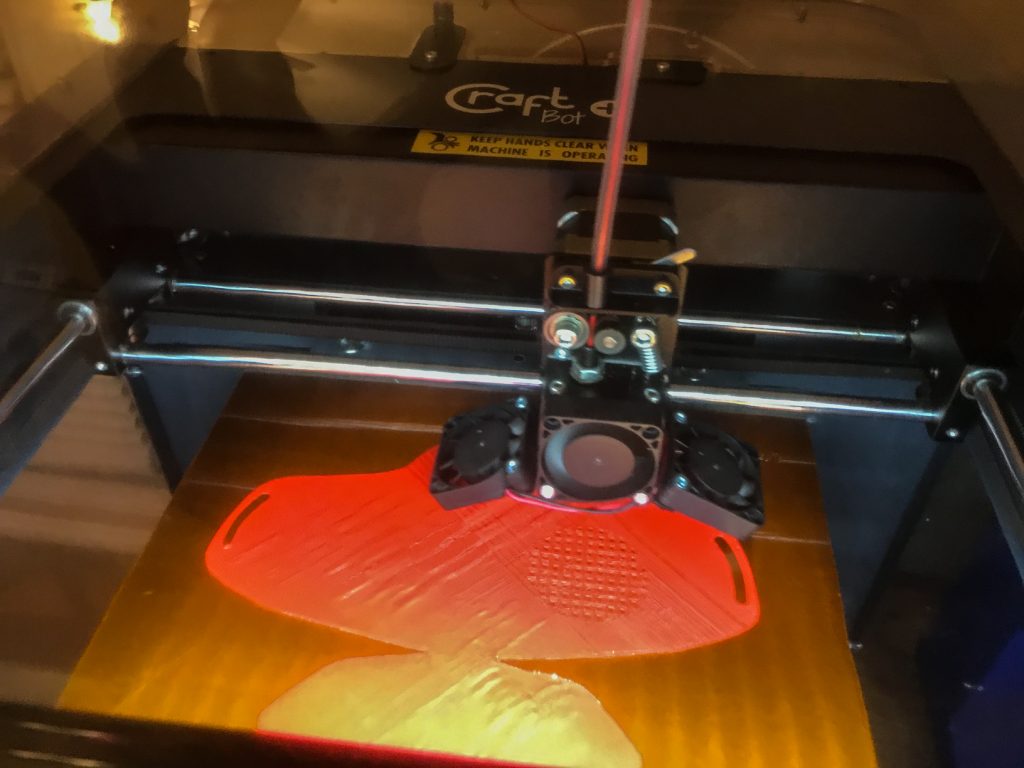

After adjusting technical settings for the 3D printable model, Malone produced a prototype similar to an N95 mask.

While Derby’s campus remains closed under Gov. Charlie Baker’s orders, students are continuing to develop their engineering skills while seeing the relevant application of their curriculum. As part of Derby’s Distance Learning program, they can send their design files to Malone to print them off-campus.

“Despite working remotely, this technology is still available to our students and curriculum,” said Malone. “This is a great opportunity to embed 3D design projects into core disciplines.”

With the fabrication and transfer time being nearly two hours per mask, Malone could potentially produce nearly 15 masks per day with the assistance of two 3D printers running throughout the day -- a worthwhile and valuable effort to help meet the growing demand for protective masks.

With Derby’s help and the efforts of other Hingham groups and individuals -- and with the worldwide, coordinated effort of startups, schools, and companies helping to manufacture the masks -- the overall effort has the potential to make a global impact, Malone said.

She hopes to drop off a collection of face masks to local hospitals and/or first responders in the coming days and weeks.